Under the SuperYacht France pavilion, we presented two SY projects currently under construction.

A big thank you to everyone who came to meet us and exchange ideas with us at our stand during the Düsseldorf trade show!

Discussions that give real meaning to our projects.

It was a truly great show, rich in high-quality encounters, inspiring exchanges, and promising new opportunities.

In 2026, a few years after the company was founded in 2018, this event marks a new milestone in a journey built with consistency and conviction. We have stayed the course by combining eco-responsibility, performance, and a passion for detail, while nurturing the unique character of every project we support.

Thank you for your trust, your curiosity, and your enthusiasm!

We look forward to continuing these discussions and building the projects of tomorrow together.

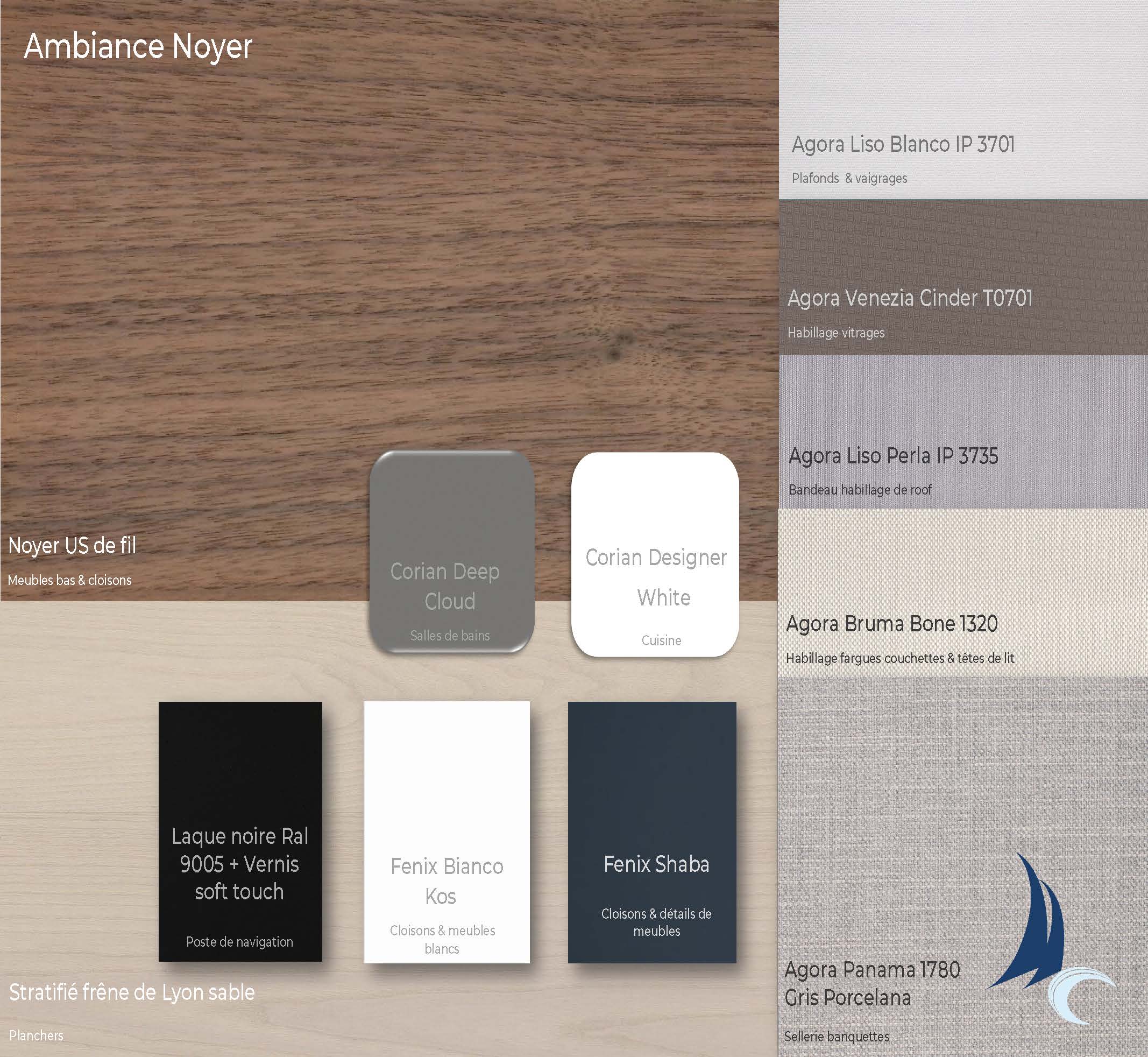

Under the spotlight, our materials library dedicated to our technical fit-out panels was a real success.

Dream Racer Boats : a design office integrated at the heart of a production workshop

This unique organization lies at the core of our approach and the value we bring to every project.

Design conceived to be manufactured

At DRB CONCEPT, design is never disconnected from the reality of the shipyard.

Every aesthetic intention, every material choice, every layout detail is conceived in direct connection with internal or external production capabilities.

Being a design office embedded within a workshop allows us to:

- design realistic, controlled, and optimized layouts,

- anticipate manufacturing, assembly, and installation constraints from the design phase,

- guarantee perfect consistency between intention, design, and execution.

Design thus becomes an industrial tool, serving performance, durability, and perceived quality.

Design, prototyping, production: a short and controlled cycle

Interior refit projects and the preparation of sailing yachts for refit give us a privileged perspective on the diversity of naval constructions. Each yard has its own technical choices, with their advantages and constraints. Working on existing structures is a real challenge: it requires flexibility, adaptability, and industrial intelligence.

This refit work, carried out in close collaboration with owners, fuels our creativity and enables us to offer innovative interior design proposals to brands and shipyards as part of their new-build projects.

Creation of finger pulls for the new OGHAM YACHTS range.

On every project—refit or new build—we provide a tailor-made response:

- a design consistent with the sailing program,

- a choice of materials adapted to performance, usage, and durability,

- a global approach to operating mode and maintenance,

- solutions tested, adjusted, and validated directly in the workshop.

To optimize a boat’s life cycle, we develop manufacturing processes capable of rapidly adapting to existing structures. Modular, scalable solutions designed to support the boat throughout its history and meet the expectations of a new owner, without compromising on quality.

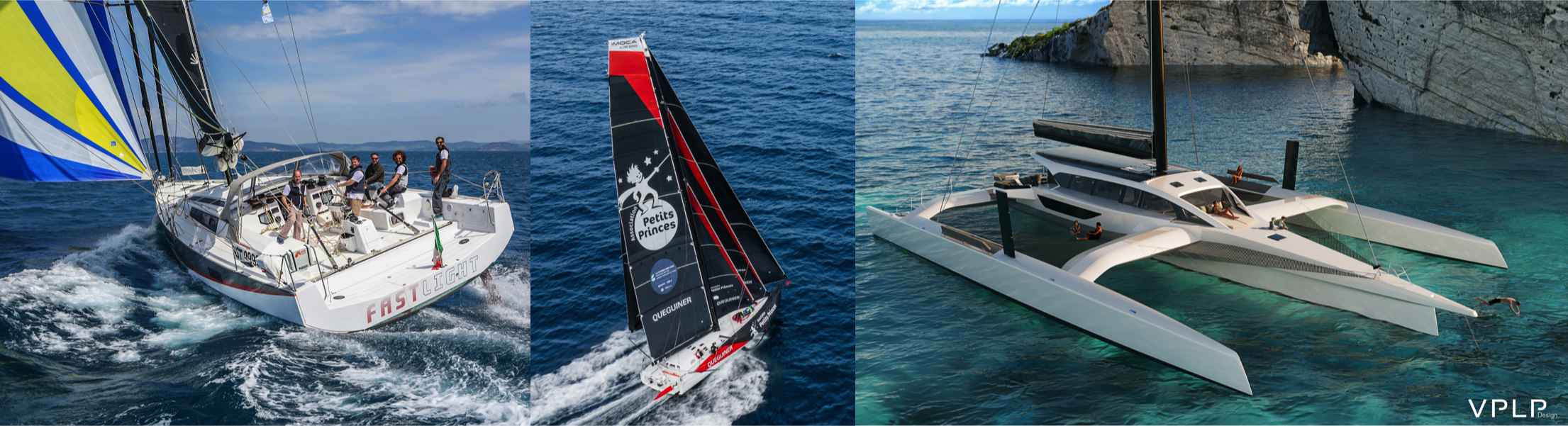

Expertise serving all sailing programs

Racing yachts, cruising yachts, production boats, exploration vessels, charter operations, or superyachts:

each market has its own codes, requirements, and uses.

To address this, we have structured specialized centers of expertise, capable of engaging equally with owners, captains, and shipyards.

DRB : integrated centers of expertise

This comprehensive approach is based on in-house centers of expertise:

a design studio,

a team of draftsmen and designers (layouts, systems, custom parts),

production lines (high-performance panels, machining, fit-out kits),

carpentry, composite, painting, and varnishing departments,,

a field team dedicated to onboard installation.

Our services, from the initial idea to the boat launch

À la carte services, designed to meet each specific need precisely.

Design

Creation of lightweight, streamlined interiors designed around a personalized sailing program.

Engineering

A key service to move from design to manufacturing, with dedicated support for industrializing the fit-outs.

Materials

Manufacture and sale of custom high-performance technical panels, with layup plans and finishes adapted to each application.

Fit-out kits

Flat-pack kits, ready to assemble, with detailed instructions.

Pre-assembled kits, ready to install onboard, with installation and systems-routing guidelines.

Turnkey project

Comprehensive project management, all the way through to handover of the boat.

From design to the delivery of a ready-to-install fit-out kit.