Towards enhanced in-house manufacturing: a year of evolution.

The value of time, the beauty of detail.

11

new talents

450

high-performance paneling

250 square meters

additional production area

2

SUPER YACHTS

Building excellence, step by step

Between innovation, precision and know-how, a year dedicated to creating the future of high-end interior design.

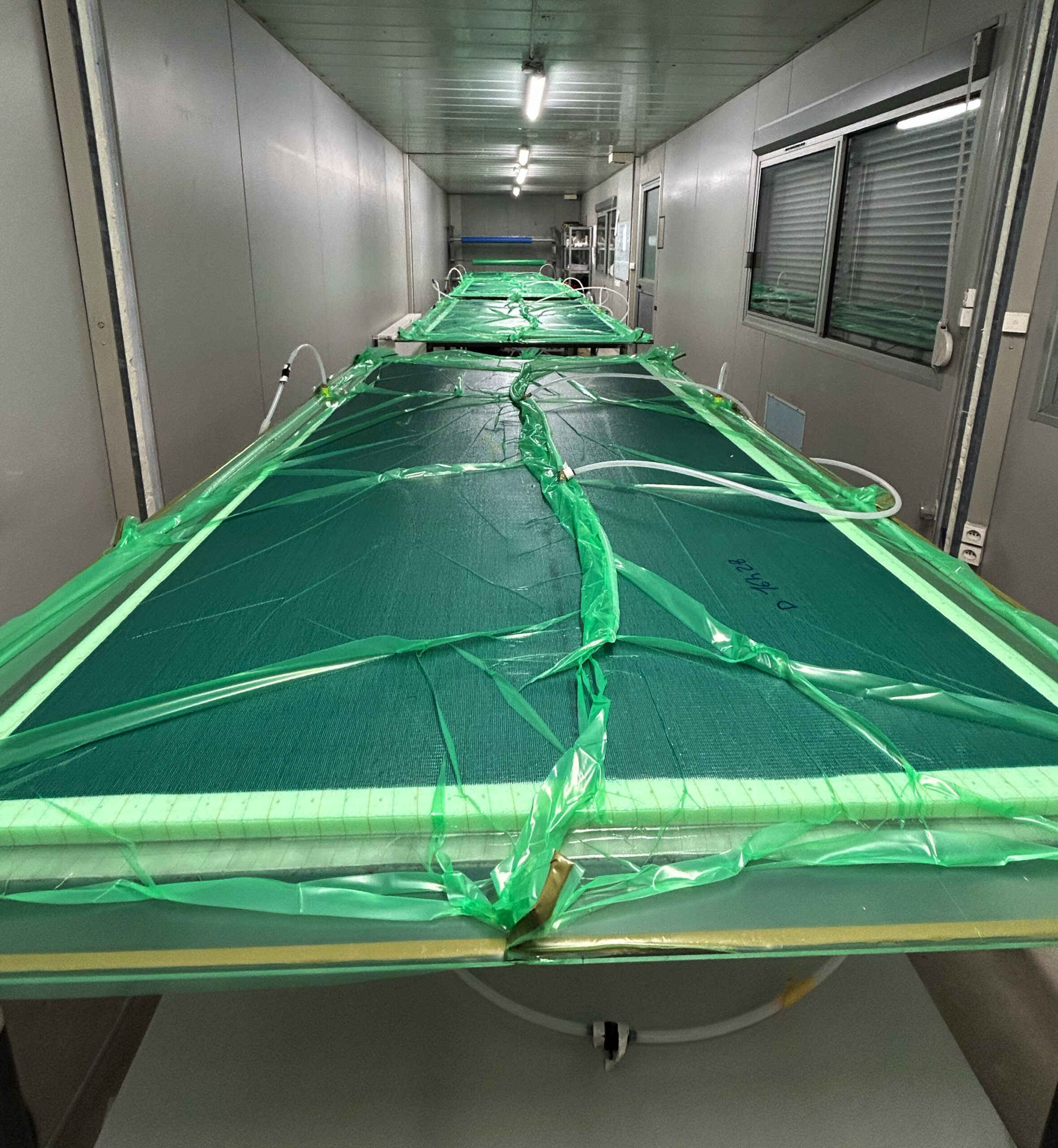

Raw material production, its transformation for high-performance interior design, and preparation to luxury standards. All this is achieved through a combination of cutting-edge technology and a highly skilled workforce. This is the result of a full year dedicated to establishing a production line, standardizing processes for high-performance interior design (for example, interior design using Nomex® panels), and welcoming 11 new talents to our teams, each with remarkable experience in high-end interior design.

This range was designed to lighten the load on boat interiors, but that’s not all. We also wanted a material that required no post-treatment to reduce its selling price, while ensuring it was durable, UV-resistant, and easy to maintain (sponge cleaning).

An initial order of 300 panels is currently in production.

Several new ranges are under development and will be launched in 2026. We can already mention the Isolabil range, a paneling designed to line the interiors of long-distance cruising boats. This new range is inspired by the first range, incorporating a natural, insulating core.

Acquisition of an edgebander using Reactive Polyurethane (PUR) adhesive

To meet the growing demand for durability and performance of materials used in fittings, edge banding using PUR is the ideal solution, which is why we have chosen to invest in this state-of-the-art equipment.

In a few words, what are its advantages?

Resistance to humidity and heat

Once hardened, PUR glue is highly resistant to water, steam, and high temperatures. It is ideal for humid environments (kitchens, bathrooms) or furniture subjected to temperature variations.

Very thin glue line to meet luxury requirements

Less adhesive can be used with PUR while maintaining a very strong bond. The joint is therefore very discreet, which improves the aesthetics, especially on light edges or visible surfaces.

A range of finishes depending on the furniture range chosen

Application of industrial, automotive, or yachting paint. Each of these solutions requires a specific application technique and the selection of the desired color. We have developed these different solutions to meet the diverse requirements of each market.

This application work was also carried out on the varnishes to meet the wishes of each owner (mirror varnish, ultra-matte varnish, water-resistant varnish, etc.). We adapt to each owner’s design.

The integration of the luxury market

NOMAD VII

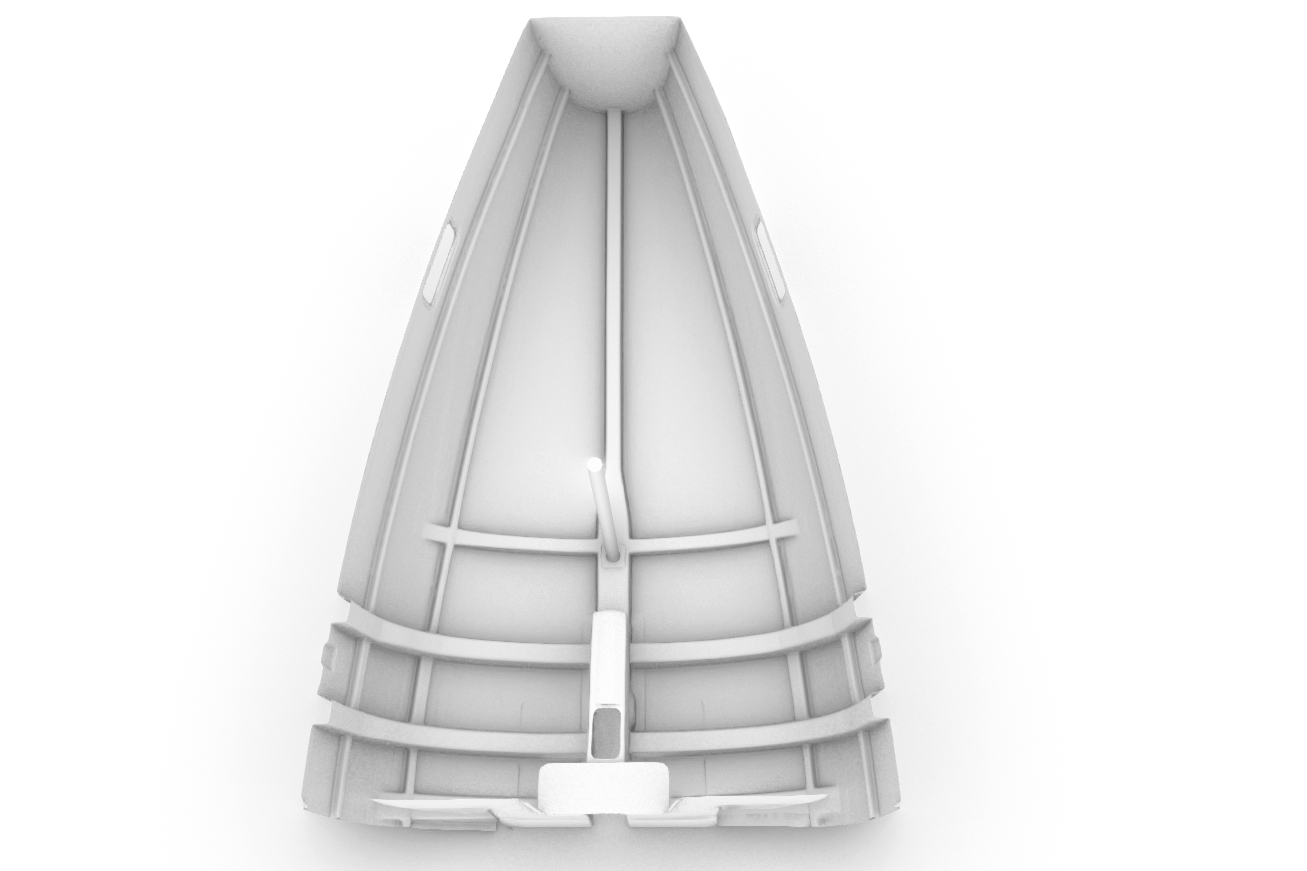

This 125-foot cruising catamaran was designed to sail at speeds of up to approximately 30 knots.

ANAHITA

This first 100-foot cruising trimaran in the world opens a new era in the world of exceptional yachting.

Our desire to always push our thinking further has allowed us, in this year 2025, to access the luxury market with the signing of two SuperYachts.

Always at the heart of our business: the design, conception, refit, preparation of sailboats and the manufacture of custom parts.

A few selected projects are listed below.

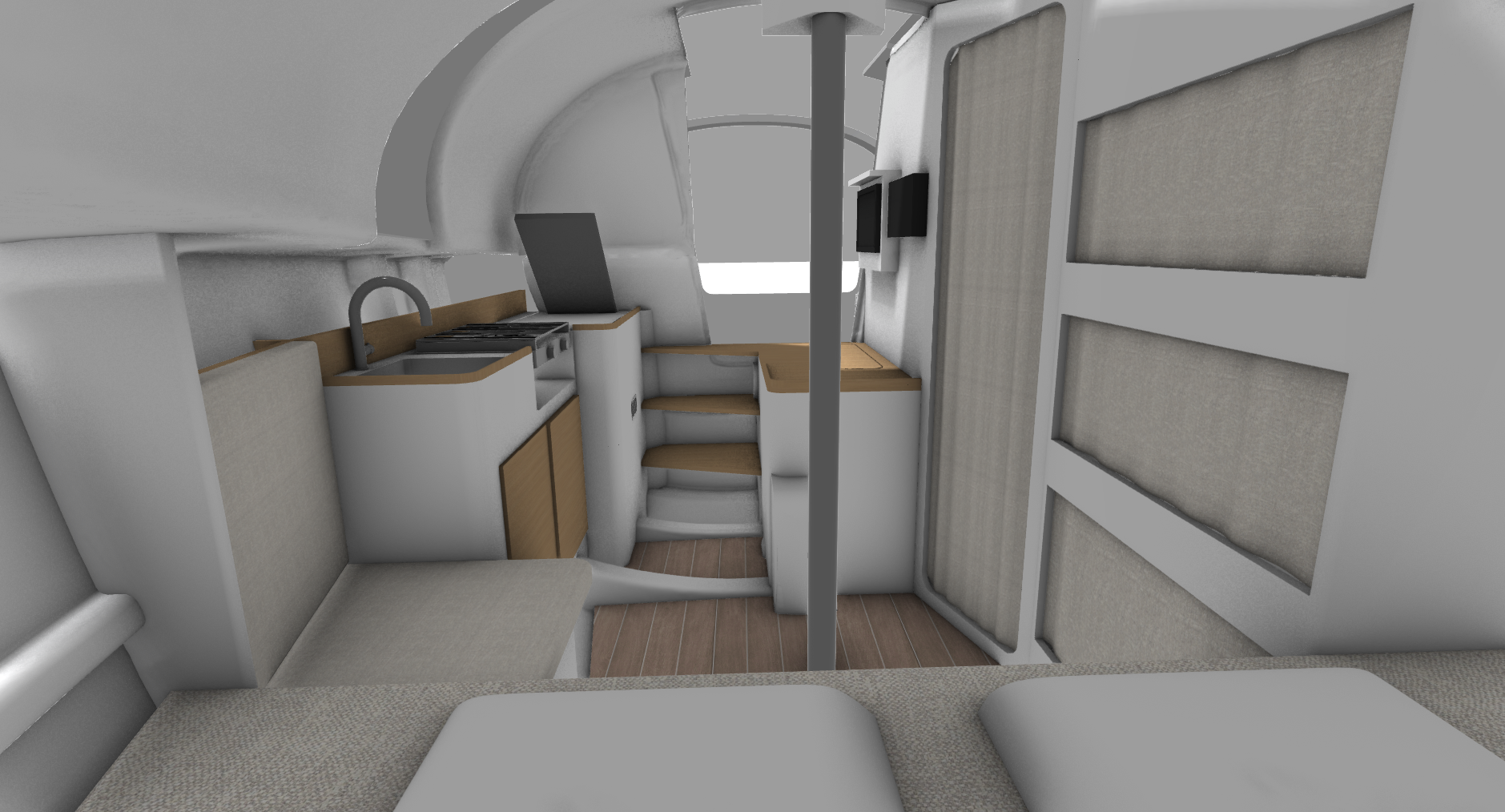

OGHAM 54

A signature of our design agency DRB CONCEPT for the interior design of this long-distance cruising yacht.

Our production workshop took over, producing the fittings in a ready-to-install kit.

Michel Desjoyeaux

Michel Desjoyeaux and his team entrusted us with the machining of the deck mold frame of the Agité 40. Michel’s class 40, which recently participated in the Café L’Or transatlantic race, in association with Alexandre Le Gallais.

Kaidoz 31

A signature of our design agency DRB CONCEPT for the interior design of this long-distance cruising yacht.

Our production workshop took over, producing the fittings in a ready-to-install kit.

Figaro 2

A refurbishment and preparation of Figaro 2 No. 36 for Cap Martinique.

Following an orca attack off Cape Finisterre, we initially replaced what remained of the original rudders with a new pair. A complete engine overhaul and a complete overhaul of the NKE electronics were undertaken. A refit of the winches and deck hardware, damaged by time, was also necessary. Then, a few comfort features were added to improve comfort during the upcoming transatlantic crossing. Finally, regarding safety, all the equipment was inspected and/or replaced.

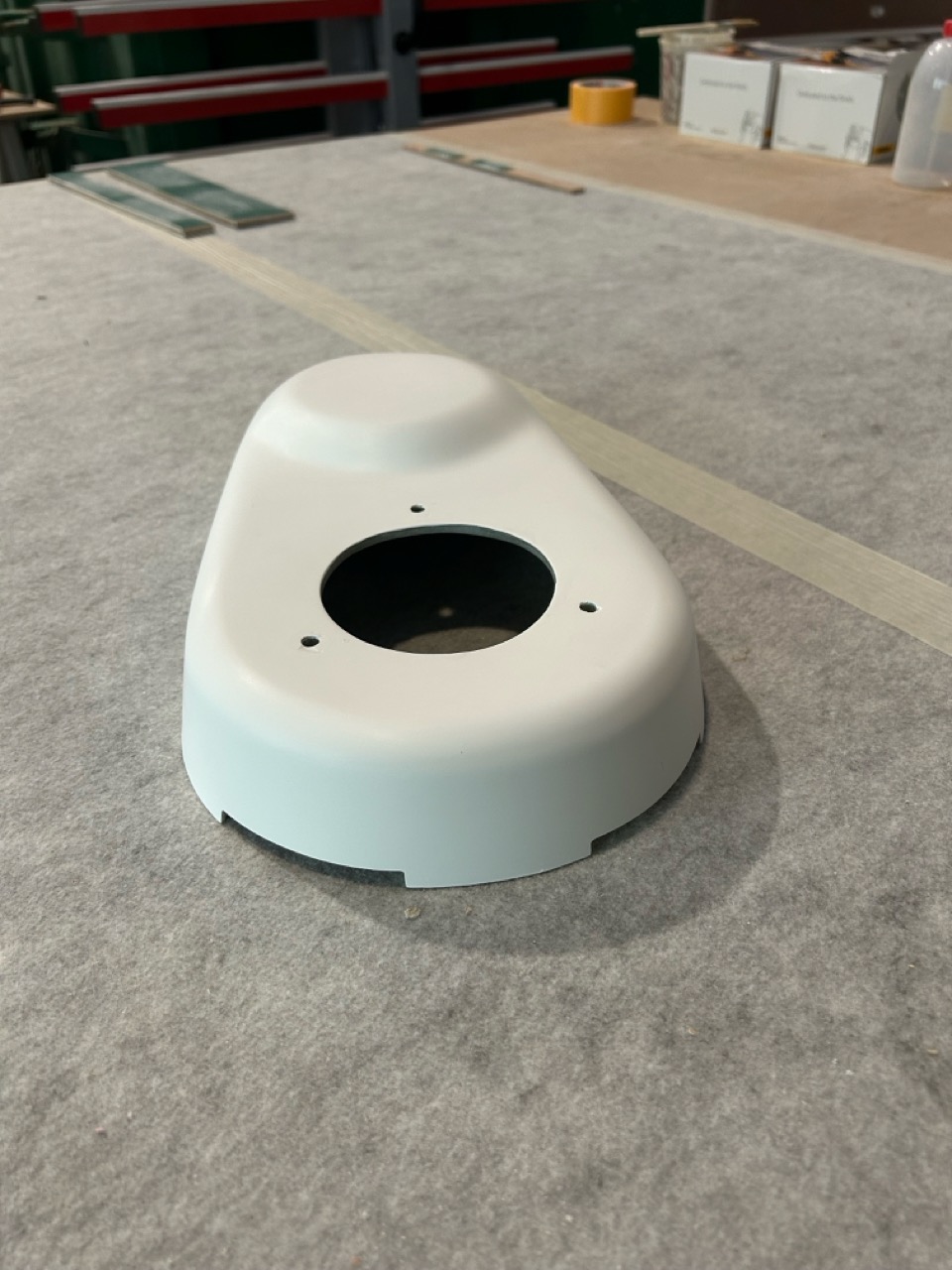

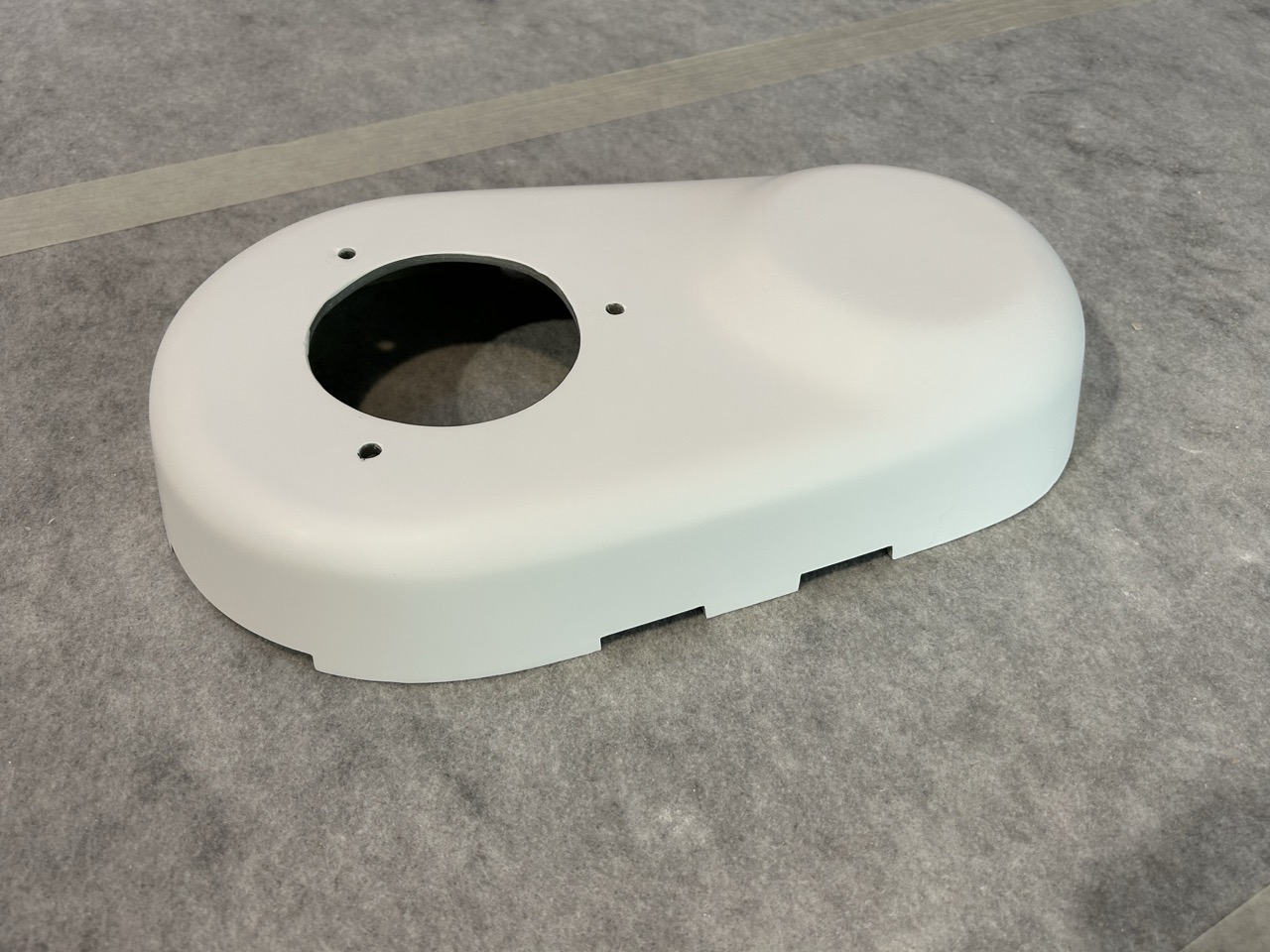

Manufacturing of composite sea bream boxes

With a view to continuous improvement, the owner of the Patago 50 commissioned us to replace the ABS dorade boxes.

For long-distance cruising, commercially available ABS parts are too fragile. We therefore created a mold and began manufacturing a composite Dorade box (monolithic glass/polyester). Highly resistant and with a polyester topcoat, this new part is perfectly suited to our client’s sailing program.

Manufacturing a removable, sturdy and lightweight cockpit table

Following its initial sea trials (Ireland & Scotland), the owner of the Patago 50 commissioned us to create a cockpit table tailored to his expectations.

These initial trials allowed our client to familiarize themselves with the onboard setup and to truly define their needs both while sailing and at anchor. The cockpit table needed to be lightweight for easy storage, yet also very robust and durable. We opted for a very lightweight core, structured surfaces coated with epoxy paint. This was combined with the selection of Burmese teak, renowned for its quality, stability, and durability.

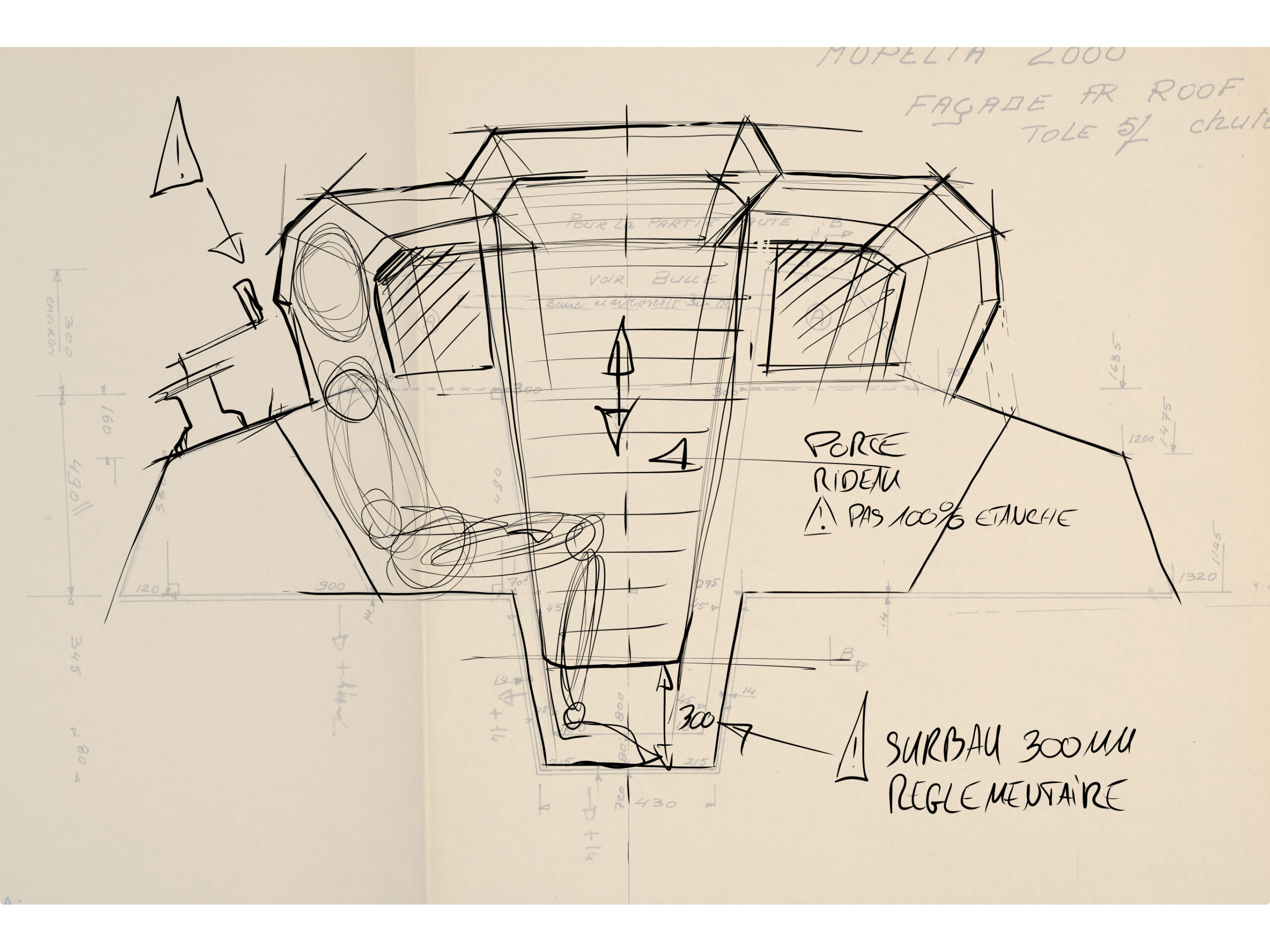

Refit : Mopelia 2000

Previously the owner of a Pogo 8.50, our client selected this 1983 sailboat for his travel plans. A seaworthy, robust sailboat of reasonable dimensions.

In this renovation project, the client, a former professional in the nautical industry, consulted us for comprehensive support. Initially, his wish was to optimize the deck layout by integrating a rigid sprayhood. This would significantly improve onboard comfort: protection from sun, rain, and spray, enhanced cockpit livability, and more serene sailing in all weather conditions.

Our approach is based on a personalized study of the existing boat, careful integration with the sailboat’s lines, and the use of appropriate materials. Each cockpit canopy is designed to integrate harmoniously, without altering the boat’s character.

In a second phase, a refurbishment of the electronics and interior layout will be considered.

By calling on our expertise, you are choosing a tailor-made solution, designed to extend the use of the sailboat, improve the comfort of the crew and enhance the value of the boat.

Thank you to all our collaborators that helped make 2025 a great sucess.

The entire DRB team wishes you a wonderful Christmas filled with happiness and

a sense of escape.

May this festive season be the opportunity to make your dreams of adventure at sea come true.

Happy holidays!